During tough economic times, management too often looks only at cutting labor costs to save money. Benefits such as holidays are cut. Wage increases are canceled. Hours are cut or workers are laid off. The savings are small and result in lower morale and lower productivity, as workers are forced to work harder for the same or lower wages.

Where workers are unionized, a good alternative to cutting labor is to reduce energy costs. The union can and should negotiate how the company can save money and jobs by using energy more efficiently. Many energy saving practices also require the cooperation and support of employees, which is best accomplished through collective bargaining instead of management making rules and changing policies.

The cost savings from using energy wiser and smarter can be considerable.

The United Parcel Service (UPS) saved millions of dollars by using mapping software to design routes for their drivers. The software minimizes the number of left turns, because left turns require drivers to wait until traffic is clear, wasting time and gas. Left turns are also more likely to result in an accident involving another vehicle or pedestrians, according to studies of accident statistics by cities and the American Automobile Association (AAA). In 2006, after two years of starting the program, UPS saved 3 million gallons of gas and shaved 30 million miles off routes, saving time and money.

Energy Star

The U.S. Environmental Protection Agency and U.S. Department of Energy run a website called Energy Star with information and plans for reducing energy costs. See http:// www.energystar.gov/index. cfm?c=about.ab_index.

The Energy Star website provides examples of the money that can be saved by different types of businesses by reducing their energy costs.

Energy Star estimates the hospitality industry spends about $7.5 billion a year on energy. Reducing energy costs by 10 percent can save $745 million. A hotel that reduces energy costs by 10 percent is equal to increasing RevPAR by $2.00 for full-service hotels and $0.60 for limited service hotels. These are national averages and the savings for Hawaii would be as much as $8.00 per room sold because of our high electricity costs and higher RevPAR.

Retail companies spend nearly $20 billion on energy each year. A 10 percent decrease in energy costs has an equivalent impact on operating income as a 1.26% increase in sales for the average retail store.

Healthcare organizations spend nearly $8.8 billion on energy each year to meet patient needs. Every dollar a nonprofit healthcare organization saves on energy has the equivalent impact on the operating margin as increasing revenues by $20 for hospitals or $10 for medical offices.

Real examples

The Energy Star website has examples of how companies saved money by reducing energy costs. HEI Hotels and Resorts saved 23.7 million kWh over a three year period from 2005 to 2008. Based on Hawaii’s $0.40 per kilowatt, this is savings of $3.17 million a year. Their biggest savings came from replacing 100,000 fixtures with high efficiency T-8 fluorescent lamps and CFLs ($1 million a year) and installing heating and air-conditioning controls in each guest room ($800,000 a year). The cost of these systems were recovered within 3 years, after which the savings goes straight to the bottom line in lower operating costs. One HEI property, the Crowne Plaza Riverwalk in San Antonio, Texas, highlights the significant financial and environmental benefits that can be achieved through smart energy changes. With 21 floors, 410 guest rooms, and extensive meeting space, this four-diamond full-service hotel started an energy saving program in 2006. They started with the easiest and least expensive steps—they cleaned heating and air-conditioning coils, installed high efficiency lighting and programmable thermostats in guest rooms, and used variable frequency drives on large motors.

The Crowne Plaza Riverwalk successfully reduced its electricity consumption by 26 percent within a two-year period, and reduced natural gas consumption by 13 percent within four years. This translates into over 2.5 million kWh or $500,000 a year. Workers were trained to create a culture of energy awareness and monthly prizes were given to employees who submitted the best energy saving idea. [see http://www.energystar.gov/index.cfm?c=hospitality. bus_hospitality]

Family savings

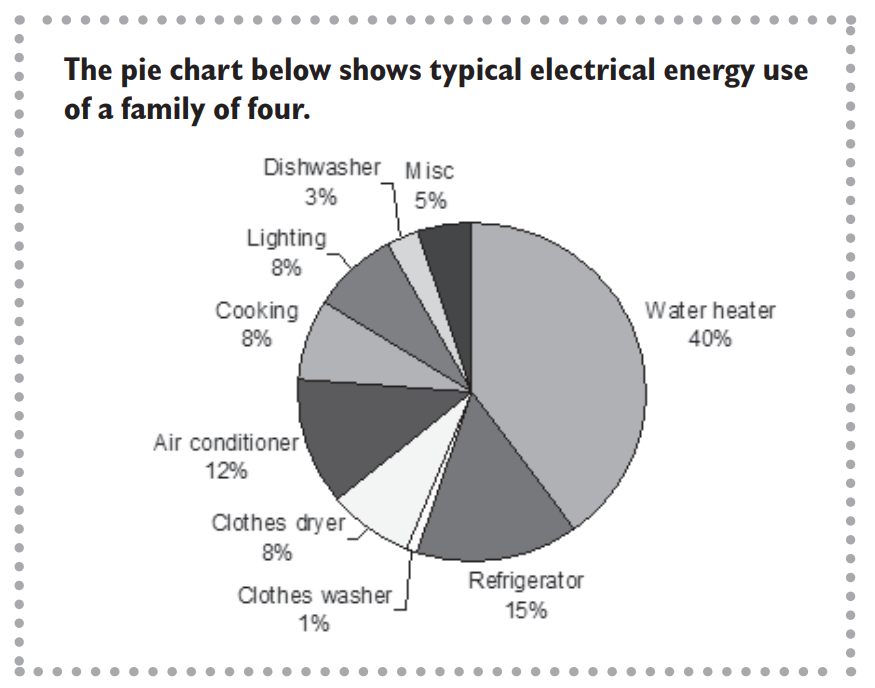

Your family can also save money by using energy more efficiently and wisely. The Energy Star website has a section on how you can make simple changes in your home to save money by reducing your electric bills. The Hawaii State Department of Business, Economic Development and Tourism has some guides on saving money on cooling your home. See their brochure on Comfortable Homes in Hawaii and Hawaii’s Homeowner’s Guide to Energy, Comfort and Value at http://hawaii.gov/ dbedt/info/energy/efficiency.

The Hawaiian Electric Company estimates the typical utility bill in Honolulu is about $90 per month and higher on the Neighbor Islands. The cost jumps up to more than $200 per month for air conditioned homes. Insulating the roof, venting hot air from the attic, and using ceiling fans are alternatives to air-conditioning which can save $30 to $50 per month.

Hope for Kauai ethanol

Pacific West Energy is moving forward with its plans to build a biofuel ethanol plant on Kauai. The company purchased the former Kekaha Mill and has begun removing asbestos and cleaning up the site. Pacific West hopes to complete a 20-megawatt biofuel plant in 2012 and sell electricity to Kauai Island Utility Cooperative.

Pacific West and Gay & Robinson (G&R) were going to form a partnership to produce energy, but this fell through when G&R phased out of sugar in 2009 and leased its lands to Dow Agrosciences and Pioneer HiBred to grow seed corn.

In 2006, Hawaii required gasoline sold in the state to be a blend of at least 10 percent ethanol and offered tax incentives for the construction of ethanol plants. The state must import over 500 million gallons of gasoline a year and the 10 percent ethanol would be about 50 million gallons. The idea was to encourage local companies to use sugar cane or other plant material to produce ethanol. This is a common practice in Brazil where sugar mills can produce sugar or ethanol as needed.

Hawaii was paying a wholesale price of $2.00 - $3.00 a gallon for gasoline and if 50 million gallons of ethanol could be produced locally, it would keep $100 million in the Hawaii economy and create hundreds of jobs.

A number of companies began exploring ethanol production, but after ethanol hit a record high of $4.23 a gallon in June 2006, prices fell to a low of $1.40 a gallon in 2008. Ethanol producers need a price of about $2.00 a gallon to make money. In 2010, ethanol prices are now running about $2.20 a gallon.